If you’re interested in machining, a metal lathe is an essential tool that you should learn to use. It’s a versatile machine that can be used to create a wide range of parts and pieces, from simple pins to complex engine components. However, if you’re new to machining, using a metal lathe can seem intimidating. In this article, we’ll walk you through the basics of how to use a metal lathe for beginners.

Safety First

Before we dive into the details of how to use a metal lathe, let’s start with the most important aspect: safety. A metal lathe is a powerful machine that can cause serious injury if not used properly. Here are some safety tips to keep in mind:

- Always wear eye protection: Flying debris can cause serious eye injuries.

- Wear proper clothing: Loose clothing or jewelry can get caught in the lathe, leading to serious injury.

- Never wear gloves: Gloves can get caught in the lathe and cause serious injury.

- Keep long hair tied back: Hair can also get caught in the lathe, leading to injury.

- Always turn off the machine before making any adjustments: Never make adjustments while the lathe is running.

- Be aware of the cutting tools: The cutting tools can become very hot during use, so be careful when handling them.

- Keep the work area clean: A cluttered work area can lead to accidents.

- Always follow the manufacturer’s instructions: The manufacturer’s instructions will provide important safety information specific to your machine.

Getting Started

Now that you know the basics of how to stay safe while using a metal lathe, let’s dive into the details of how to use one.

- Familiarize yourself with the machine: Before you start using the lathe, take some time to familiarize yourself with the machine. Look at the controls, read the manual, and make sure you understand how the lathe works.

- Choose your material: The metal lathe can be used to cut a variety of materials, including aluminum, brass, steel and plastic. Choose the material you want to work with and make sure it’s securely mounted in the chuck.

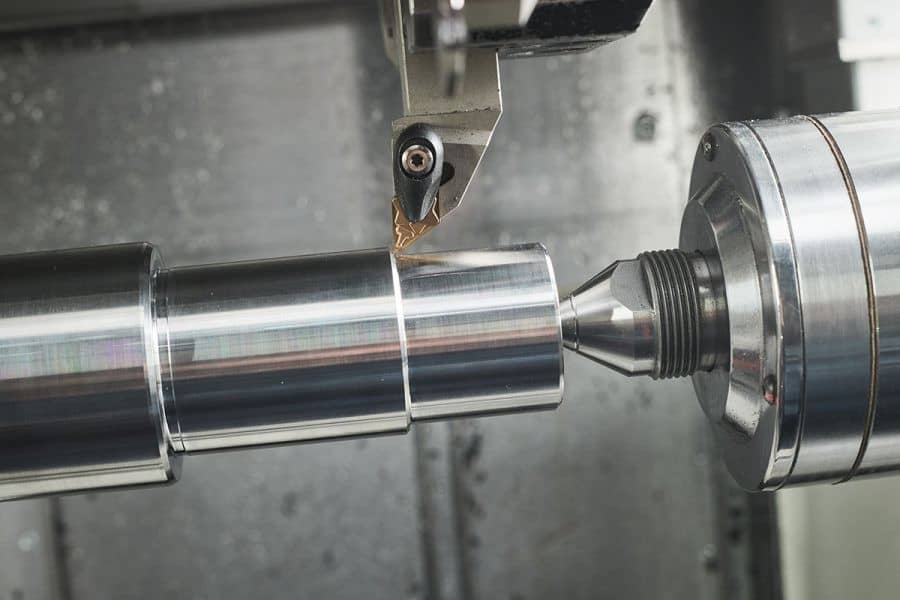

- Set the cutting tool: The cutting tool is what you’ll use to shape the material. Make sure it’s securely mounted in the tool post and adjusted to the correct height. Look to align the tool to the center of your workpiece.

- Adjust the speed: The speed at which the lathe spins will depend on the material you’re working with and the type of cut you want to make. Consult the manufacturer’s instructions to determine the appropriate speed.

- Start the lathe: Turn on the lathe and slowly increase the speed until you reach the desired RPM.

- Take your first cut: With the lathe running, bring the cutting tool into contact with the material starting at the end of the material furthest away from the chuck. Take a small cut to start and gradually increase the depth as up remove more material.

- Check your work: As you make cuts, periodically stop the lathe and check your work. Make sure you’re achieving the desired shape and that there are no signs of overheating or other issues.

Advanced Techniques

Once you’ve mastered the basics of how to use a metal lathe, there are a variety of advanced techniques you can learn to create even more complex pieces. Here are just a few examples:

- Thread cutting: The metal lathe can be used to cut threads on a variety of materials. To do this, you’ll need a special cutting tool called a threading tool. Consult the manufacturer’s instructions to learn how to set up the threading tool and create threads on your material.

- Taper turning: Taper turning is the process of gradually reducing the diameter of a workpiece. This technique is often used to create pieces such as

- tapered pins or cones. To do this, you’ll need to adjust the angle of the tool post to match the desired taper angle and make gradual cuts as you work your way down the piece.

- Facing: Facing is the process of creating a flat surface on the end of a workpiece. This technique is often used to create pieces such as washers or spacers. To do this, you’ll need to adjust the cutting tool so that it’s perpendicular to the workpiece and make cuts until the surface is flat and smooth.

- Knurling: Knurling is a process used to create a pattern of small ridges on the surface of a workpiece. This technique is often used to improve grip on handles or knobs. To do this, you’ll need a knurling tool and to adjust the tool post to the correct angle. Then, slowly move the tool along the workpiece, applying pressure to create the desired pattern.

- Drilling: While a metal lathe is not specifically designed for drilling, it can be used to create holes in metal pieces. To do this, you’ll need to secure a drill bit in the tailstock and adjust the height and angle of the tailstock to match the desired hole location. Then, slowly feed the drill bit into the material while the lathe is running.

Conclusion

Using a metal lathe can be an intimidating process for beginners, but with practice and proper safety precautions, it can become a valuable skill for machining a variety of metal parts and pieces. Remember to always prioritize safety when using the lathe, familiarize yourself with the machine before starting, and start with small cuts before moving on to more advanced techniques. With time and practice, you can become proficient in using a metal lathe to create complex and precise metal pieces.