With electric cars taking over the automotive landscape, it’s important to understand how electric cars actually work.

Tesla and other EV (electric vehicles) operate purely on electrical motor-based input and utilizes electricity as their main source of power. Electric cars have zero emissions, and receive their fuel source by plugging into a wall outlet instead of pulling up to the gas station.

To get a better idea of how exactly electric cars function, let’s take a look at some of the different parts and features that make up these vehicles.

Understanding the Components of an Electric Car

In order to understand how electric cars work, we must first understand the components that make up these vehicles. Similar to your normal combustion engine, electric cars have their own energy conversion system. Instead of converting gasoline, they instead convert electricity into the power that moves them.

The Most Important Piece: The Traction Battery Pack

The single most important piece of an Electric car like Tesla’s, is what’s known as the traction battery pack. This battery is single handedly responsible for storing the electricity responsible for moving the vehicle. This should not be confused with the auxiliary battery, which we’ll cover shortly.

The Power Electronics Controller Does an Essential Job

The power electronics controller is responsible for the proper delivery of stored electricity to the electric traction motor. Thanks to this device, you’re able to control the total delivered power and, in turn, the total torque output. It’s easiest to remember it as the device that best represents a throttle on your standard combustion engine vehicle.

Electric Traction Motor is Essential for Movement

With the help of the power electronics controller, the electric traction motor is what actually moves the electric car. The power electronics controller converts the electricity into usable electricity from the traction battery pack, which the electric traction motor then uses to propel the vehicle forward or backward.

The electric traction motor is essentially the electric variant of the gas motor. They are similar in their job, however, the energy utilized is what is different.

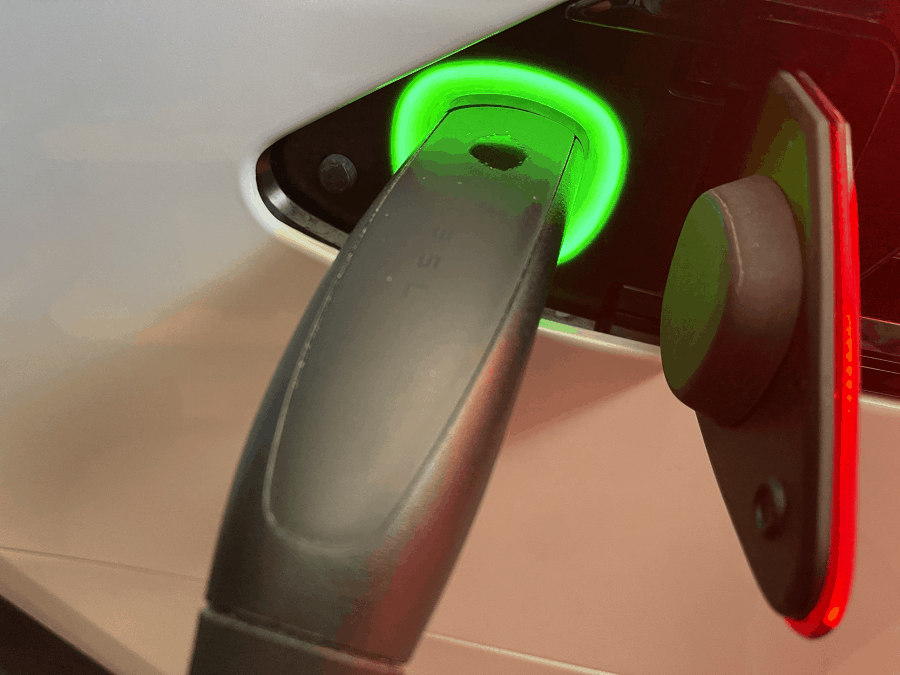

The Charging Port is Used to Power Up

Similar to a combustion engine car, electric cars require a place to refuel, or charge in this case. This is where the charging port comes into play. Typically located in a similar location as the fuel neck on a gas car, the charging port is simply the place on your electric car that allows it to be plugged in to charge.

Onboard Charging Device Converts from AC to DC

Whether at home or a charging station, the power supplied to charge your electric vehicle is most often supplied in its AC variant. Since electric vehicles utilize DC power, a conversion must take place in order for the vehicle to utilize it in its charging system. The onboard charging device takes care of this conversion, and also allows you to monitor the overall health of your batteries and charging system.

Cooling System or Thermal System

Much like your standard gasoline powered car, electric cars create heat as a bi-product with extended use. In order to better manage this heat, electric cars are equipped with cooling systems to better regulate the temperature of the onboard computers and electronics within the vehicle.

When comparing it to a traditional automotive system, think of your radiator and surrounding pieces that influence it. The goal of this cooling system is to reduce the total heat being put off by the power source by introducing something that cools it down.

Auxiliary Battery for Accessories or Electronics

The auxiliary battery should not be confused with the traction battery pack, as it serves a different purpose entirely. The auxiliary battery is responsible for storing and supplying the electricity to the many other electrical needs of the vehicle. These are usually things like lights and other convenience features.

Auxiliary batteries have long served their purpose in automotive application, most often used to power features available in the vehicle. Instead of an alternator powering it through driving, electric cars use a DC converter that delivers power from the traction battery pack.

DC Converter Transforms High Current to Low Current

While the auxiliary battery and the traction battery pack both require electricity to operate, they utilize different forms of DC power. The DC converter is responsible for converting the high-voltage DC power utilized by the traction battery pack into the lower-voltage DC power needed by the auxiliary battery to power your electronics.

The process done by the DC converter is much less invasive than the AC to DC conversion done at the onboard charging device. While some electricity is lost at this conversion, it’s minimal loss overall. Rather than changing formats, it’s actually just decreasing the level of voltage.

Electrical Transmission Does a Lot of the Heavy Lifting

The electrical transmission is responsible for getting the vehicle moving. It takes the mechanical power output by the electric traction motor and uses it to physically drive the wheels. Without the electrical transmission, the vehicle would be unable to use the electricity stored to move the vehicle.

The electrical transmission is similar in concept to a standard gas car transmission in function only. It takes the power created by the motor, and transforms it into energy that can be used to turn the wheels and get the car moving.

Visualizing How All of the Parts Come Together

Now that you understand the parts that make up an electric vehicle, you may still be wondering how it all actually comes together to drive. Let’s use the information provided about the parts to better visualize how they all do their own heavy lifting to create the electric car driving experience Tesla and other brands are known for.

First, You Need to get Charged Up

So, the first step in getting an electrical vehicle going is supplying it with the electricity it needs. Tesla has their patented Super Chargers scattered through the US and assuming you have the correct hardware installed, you can even charge it at home.

You’ll connect the power plug into the charge port the same way you would fill your standard vehicle with gasoline. From there, the onboard charger will do its work, converting the incoming AC into DC power utilized by the vehicles power systems. This electricity will be stored in the traction battery pack.

Think of this step as filling your standard gasoline vehicle up at the gas station. You plug in the handle, wait for the gas tank to fill up, and off you go. Instead of a gas tank, electrical vehicles are “filling up” their traction battery pack. Once you’ve reached optimal charge, you’re ready to drive.

Starting the Vehicle and Preparing to Drive

Once you have the necessary stored electricity, there are a few things that happen when you “start” your electric vehicle.

First, some of the supplied electricity is converted via the DC converter to power your electronics and features. You can think of turning a key into the on position in a regular car. Your dashboard will turn on, and your radio and other features will power up.

Thanks to the onboard charging system, you’ll be able to monitor the health of your onboard batteries, to verify you’re safe to drive. With electricity stored in both your auxiliary battery as well as the traction battery pack, your electric vehicle is just about ready to hit the road.

As You Drive the Electric Car

As you begin to drive, there are a few components that work together to get the car moving. The electricity stored within the traction battery pack acts as the gasoline used to power all of the processes the vehicle will engage in going forward.

As you begin to move, the electric traction motor takes some of the electricity stored within the traction battery pack to generate movement to the car’s wheels. The electric transmission equipped with these motors turns the mechanical power created into a usable format that can propel the vehicle forward.

This is where the power electronics controller comes in. As you adjust how much torque is delivered via the foot pedal, the speed of acceleration is then controlled by the power electronics controller based on your input. It’s like hitting the gas pedal in your regular car.

The longer you drive an electrical vehicle, the hotter the batteries and electronic systems get from prolonged use. Much like standard gas vehicles, electric vehicles are equipped with cooling systems to help regulate the overall temperature of the electronic components. Without this cooling system, you’d be overheating all the time.

An Important Note About Regenerative Technology

It wouldn’t be a comprehensive guide to understanding how electric cars like Tesla work, without the inclusion of regenerative properties. Specifically, how the brake system works to capture some of the lost energy when slowing down or stopping.

What is Regenerative Braking?

When a vehicle is slowed down using the breaks, pads are closed on a rotor in order to generate stopping power for the vehicle. The result is your vehicle coming to a stop, along with the biproducts of heat and friction.

Regenerative braking systems used by most electric cars take this generated kinetic energy and convert it back into electricity that can be stored back in the traction battery pack for later use. While regenerative braking isn’t enough to power electric cars on their own, it’s a great way to increase the efficiency of the vehicle all around.

How Do Electric Vehicles Convert and Store this Energy?

As you’re driving, the battery supplies the vehicle with power based on your input via the throttle. When you remove your foot from the throttle, the power supply is cut off from the vehicle, meaning you’ll gradually lose power as the vehicle begins to slow down

With electric cars, the motor begins to run backwards, capturing the created excess kinetic energy similar to how a generator uses friction. This captured energy used to slow down the vehicle is then stored back in the battery, meaning you’ve slowed your vehicle down and taken back some of the charge you used all at the same time.

Regenerative Braking and Regular Braking are Two Separate Things

It’s important to understand that regenerative braking does not replace your traditional braking methods used to stop the vehicle on short notice. In most cases, drivers can take advantage of regenerative braking systems by using them in scenarios where they have plenty of time to slow down, or can easily estimate how far they can go before having to come to a complete stop.

Regular braking systems, such as the pad and rotor systems mentioned previously, are still used to bring the vehicle to a complete stop at a moment’s notice. It’s best to think of the regenerative brake system as a secondary feature used to slow the vehicle down overtime, while capturing some of that energy during this period.

How Much Energy Can Regenerative Brake Systems Recapture?

How much energy regenerative brake systems are capable of recapturing is solely dependent on how the vehicle is driven. The longer the vehicle is able to slow itself down before the regular brakes are utilized, the more potential there is for total energy recapture.

Since batteries cannot receive more energy than they’re capable of storing, you won’t capture any more if your battery is on full. Batteries, in general, are unable to be overcharged, meaning you’ll miss out on some of the regenerative braking properties if you’re the type to keep your charge maxed out.

Regenerative braking is simply a way to increase the overall efficiency of electric cars overall. As they become more popular and more widely accepted as the vehicle of choice, there’s sure to be more features developed and introduced to increase the vehicles’ overall efficiency.

What Kind of Batteries Do Electric Cars Use?

Believe it or not, there are a few types of batteries out there, all of which serve a different purpose of charging. In general, electric cars typically use Lithium-Ion batteries to power their drive system. Depending on the situation and charging format, another type of battery could be a better fit overall.

Most Commonly Used: Lithium-Ion Batteries

Lithium-Ion batteries are one of the most commonly, wide-scale used batteries available on the market today. These batteries can be found in most of your household and work-related electronics, due to their high power-to-weight ratio. Simply meaning you’ll get more power with less overall weight.

Lithium-Ion batteries are commonly used to power electric vehicles too. Although slightly different than your consumer grade lithium-ion batteries, EV batteries have great high temperature performance and can be recycled for future use.

Used Less Often: Nickel-Metal Hydride Batteries

Used more in medical equipment and high-performance computers, nickel-metal hydride-based batteries offer a more even power to weight ratio. Overall, these batteries handle abuse much better, and have longer total lifecycles than any other form of battery available on the marker.

As for their function with electric cars, you’ll be hard-pressed to find them anywhere near the auto industry. Due to their high cost and above average heat generation, they’re typically avoided when it comes to vehicles in general.

The Best-Known Battery: Lead-Acid Batteries

Lead Acid batteries are among some of the cheapest available batteries available, and are considered some of the safest ones out there. Due to their low cost and high-power available options, they’ve long been used in standard vehicles to power accessories available in most cars.

In the Electric car market however, they’re much less prevalent. Due to their short life cycle and inability to deal with extreme temperatures, they’re less than ideal for vehicles that depend on them to last. Lead-Acid batteries require constant replacement and maintenance, so other than some auxiliary options, and you won’t find too many in your electric vehicles.

The Importance of Battery Recyclability

Since the goal of electric cars is to increase our overall dependability on renewable resources, it’s also important that we use batteries that can be recycled and recaptured near one hundred percent efficiency.

This is why lithium-ion batteries remain the current best choice for electric cars. While it still remains a bit pricey to recycle them, our ability to retain the majority of the resources within the battery is near full recovery. As technology gets better, the cost of battery recycling will surely decrease.

Now You Know How Electric Cars Work!

As electric vehicles continue the onward trend of dominating the automotive industry, understanding how they work becomes ever more important. While similar to gasoline powered vehicles, how they operate and the parts they consist of are of a completely different world entirely.

As technology continues to increase, and our understanding of electronics goes further, electric vehicles will only increase in their demand overall. Battery technology itself has become a force to be reckoned with, and will only increase in both dominance and capacity. Next time you see a Tesla at a Super Charger, you’ll be able to visualize what’s happening, and know how they work, The first step in becoming an expert!